Review Article- Asian Journal of Pharmaceutical Technology and Innovation(2018)

Deflouridation – A Review

Suvarna V Biradar*Dr. Suvarna V Biradar, Senior Lecturer, Department of Public Health Dentistry, HKDET’S Dental College Hospital & Research Institute, Humnabad 585330. Bidar, Karnataka, India, Tel: +918970831926, Email: suvarna13gulbarga@gmail.com

Received: 10-Jan-2018 Accepted Date: Jan 18, 2018 ; Published: 20-Jan-2018

Abstract

Fluoride is a normal constituent of natural waters and its concentration varies depending on the water source. According to World Health Organization - the standard level of fluoride in drinking water is 1.5 mg/L. The 1984 WHO guidelines suggested that in areas with a warm climate the optimal fluoride concentration in drinking water should remain below 1 mg/l (1ppm or part per million), while in cooler climates it could go up to 1.2 mg/l. The latest information shows that fluorosis is endemic in at least 25 countries across the globe. Fluoride is often described as a ‘double-edged sword’ as inadequate ingestion is associated with dental caries, where as excessive intake leads to dental and skeletal fluorosis which has no cure. Considering the fact that fluorosis is an irreversible condition and has no cure, prevention is the only solution for this menace. Providing water with optimal fluoride concentration is the only way by which the generation yet to be born can be totally protected against the disease.

Keywords

Fluoride, Defluoridation, Adsorption, FluorosisIntroduction

Water is one of the most important elements for all forms of life and is indispensable to the maintenance of life on earth. Safe drinking water is the primary need of every human being. Pure water is scarce and is not easily available at all. Water may be contaminated by natural sources or industrial effluents. One such contaminant is fluoride.

Fluoride is a normal constituent of natural waters and its concentration varies depending on the water source. According to World Health Organization - the standard level of fluoride in drinking water is 1.5 mg/L. The 1984 WHO guidelines suggested that in areas with a warm climate the optimal fluoride concentration in drinking water should remain below 1 mg/l (1ppm or part per million), while in cooler climates it could go up to 1.2 mg/l. The latest information shows that fluorosis is endemic in at least 25 countries across the globe.

Fluoride is often described as a ‘double-edged sword’ as inadequate ingestion is associated with dental caries, where as excessive intake leads to dental and skeletal fluorosis which has no cure. Considering the fact that fluorosis is an irreversible condition and has no cure, prevention is the only solution for this menace. Providing water, with optimal fluoride concentration is the only way by which the generation yet to be born can be totally protected against the disease. It can be achieved by the following methods :

• Removal of fluoride from water (defluoridation), using suitable techniques

• Locating alternative sources of safe water

• Bringing in water from a distant, safe source

• Prevention of industrial fluorosis by rigorous enforcement of procedures for minimizing industrial fluoride pollution

Various techniques and materials were tried throughout the world for defluoridation of water. Defluoridation was the conventional and widely tested method for supplying safe water to the fluorosis affected communities.

Definition of Defluoridation

It is defined as –“ the downward adjustment of fluoride ion concentration in public drinking water supply so that the level of fluoride is maintained at the normal physiological limit of 1ppm to prevent dental caries with minimum possibility of causing dental fluorosis”.1

Defluoridation is defined as – “the downward adjustment of level of fluoride in drinking water to the optimal level”.2

Characteristics of defluoridation

1) It is cost effective

2) Easy to handle or operate by the people

3) Independent of input fluoride concentration alkalinity, pH, temperature

4) It does not affect taste of water

5) Should not add other undesirable substances (example - Aluminium) to treated water

Defluoridation techniques

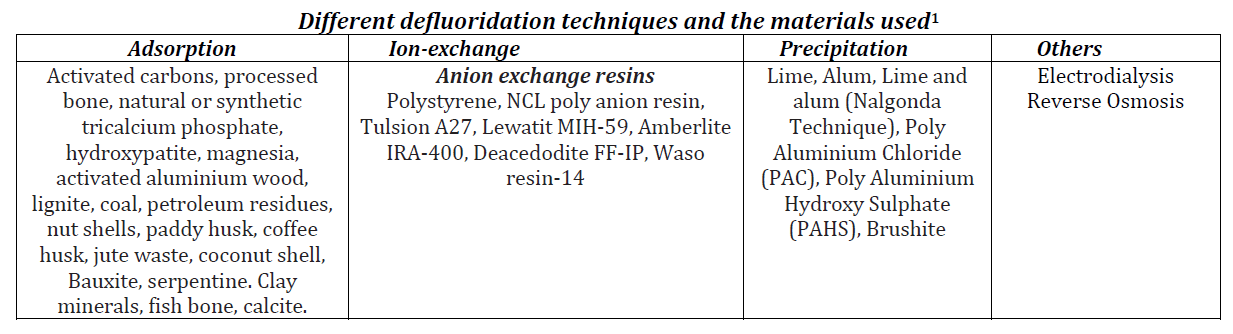

Defluoridation was the conventional and widely tested method for supplying safe water to the fluorosis affected. Defluoridation techniques can be broadly classified in to four categories. They are :

1. Adsorption technique

2. Ion-exchange technique

3. Precipitation technique

4. Other techniques, which include electro chemical defluoridation and Reverse Osmosis.

1. Adsorption technique

Adsorption is the property of a solid substance to attract and hold to it’s surface a gas, liquid or a substance in solution or suspension.

This technique functions on the adsorption of fluoride ions onto the surface of an active agent. Activated alumina, activated carbon and bone char were among the highly tested adsorbing agents.

Activated Alumina

The application of domestic defluoridation plant, based on activated alumina, was launched by UNICEF in rural India. Herschel S. Horowitz and Stanley B. Helfetz, in 1972 discussed about a successfully functioning, activated alumina community defluoridation plant, which was commissioned in Bartlet, Texas, USA in the year 1952. The plant could achieve a marked reduction in the prevalence and severity of dental fluorosis.

The disadvantages with activated alumina are :

1. Adsorption of fluoride is possible only at specific pH range, needing pre-and post- pH adjustment of water.

2. Frequent activation of Alumina is needed, which make the technique expensive.

3. Regeneration generates concentrated fluoride solution, causing disposal problems. Adsorption efficiency of the activated alumina diminishes with increasing number of usage-regeneration cycle.

Bone char

The process of defluoridation by using bone char was described by Ms. Nutthamon Fangsrekam as the ion exchange and adsorption between fluoride in the solution and carbonate of the apatite comprising bone char.The efficacy of the plant depends upon temperature and pH of raw water, duration for which the bonechar is in contact with raw water. The maximum amounts of fluoride adsorbed per gram of bone char surface at 25o, 35o and 45o C are about 21.1, 22.4, and 25.7 μ mol respectively. The optimum time for the adsorption to reach saturation is 9 hours and optimum pH of fluoride solution is between 7.00 and 7.50. It is a highly economic technique with a defluoridation percentage of 62 to 66. Further, the efficiency of the bone-char method of water defluoridation can be improved by pre-treating the raw water with Brushite and Calcium hydroxide. Herschel S. Horowitz et al in 1972 discussed the effectiveness of a defluoridation plant, which used bone char as the active ingredient and was functioning since 1948 in Britton, USA. It caused significant reduction of dental fluorosis in the local communities.

Disadvantages

1. The bone char harbors bacteria and hence unhygienic.

2. Without a regular fluoride analysis, nothing indicates when the material is exhausted and the fluoride uptake is ceased.

3. It is a technique sensitive procedure, since the efficiency of bone char as an adsorbent for fluoride is a function of the charring procedure which should be done cautiously. Moreover, the use of bone-char may invite cultural and religious objections.

Natural adsorbents

Many natural adsorbents from various trees were tried as defluoridation agents. Seeds of the Drumstick tree, roots of Vetiver grass and Tamarind seeds were few among them. The seeds of the drumstick tree (Moringa oleifera) adsorb fluoride from water. Drumstick seeds act as a coagulant. They have long been a traditional method for purification of turbid water in both India and Africa. Researchers at “M. S. Swaminathan Research Foundation”(MSSRF) had shown drumstick seeds to have remarkable defluoridation efficiency, which was higher than that of activated alumina.

The roots of Vetiver grass (Vetiveria zizanoides) were effective at defluoridation and could remove as much as 70% of the fluoride from a sample. The defluoridation efficiency was higher than activated alumina, and the price was comparable. But, the quantity of grass needed is so high that, a family would need to rise acres of Vetiver grass every year in order to provide enough material for defluoridation.

Tamarind seeds were successfully tested for defluoridation by sorption. Since maximum defluoridation is achieved at an optimum pH of 7, post defluoridation pH adjustment is not required. Tamarind seeds, which are otherwise considered a kitchen- waste, can be obtained at much cheaper price.2

2. Ion-Exchange technique

Synthetic chemicals, namely, anion and cation exchange resins have been used for fluoride removal. Some of these are Polyanion (NCL), Tul-sion A - 27, Deacedite FF (IP ), Amberllte IRA 400, Lewatit MIH - 59, and Amberlite XE – 75 [21, 22, 23, ]. These resins have been used in chloride and hydroxy form. The fluoride exchange capacity of these resins depends upon the ratio of fluoride to total anions in water. Benson et al. (1940) used ion exchange process in which sodium ions were removed from the solution by cationic material.

The hydrogen fluoride was removed during the second stage.

Drawbacks of Ion-exchange and adsorption techniques

1. The necessary flow through system is often difficult to arrange where there is no piped water supply

2. Gradual exhaustion of the active agent is not easily detected.

3. Precipitation technique

Precipitation methods are based on the addition of chemicals (coagulants and coagulant aids) and the subsequent precipitation of soluble fluoride salt as insoluble fluorapatite. Fluoride removal is accomplished with separation of solids from liquid.Alum, lime, Poly Aluminium Chloride, Poly Aluminium Hydroxy sulphate and Brushite are some of the frequently used materials in defluoridation by precipitation technique. The best example for this technique is the famous Nalgonda technique of defluoridation.

Nalgonda technique

After extensive testing of many materials and processes including activated alumina since 1961, National Environmental Engineering Research Institute (NEERI), Nagpur has evolved an economical and simple method for removal of fluoride which is referred to as “Nalgonda Technique”. Nalgonda Technique involves addition of Aluminium salts, lime and bleaching powder followed by rapid mixing, flocculation, sedimentation, filtration and disinfection. Aluminium salt may be added as aluminium sulphate (alum) or aluminium chloride or combination of these two. It is responsible for removal of fluoride from water. The dose of aluminium salt increases with increase in the fluoride and alkalinity levels of the raw water. The selection of either aluminium sulphate or aluminium chloride depends on sulphate and chloride contents of the raw water to avoid them exceeding their permissible limits. Lime facilitates forming dense flocks for rapid settling of insoluble fluoride salts. The dose of lime is empirically 1/20th of that of the dose of aluminium salt. Bleaching powder is added to the raw water at the rate of 3 mg/l for disinfection. Bulusu et al. stated in 1979 that Nalgonda Technique was preferable at all levels because of the low price and ease of handling.The technique is highly versatile and has the applications for large communities, fill and draw technique for small communities, fill-and-draw defluoridation plant for rural water supply.

For large communities

This is a combination of the processes - rapid mixing, chemical interaction, flocculation, filtration, disinfection and sludge concentration to recover water and aluminium salts. Different processes are allowed to take place in different tanks of suitable size.

Fill and draw technique for small communities

For communities with a population ranging from 200 to 2000, a defluoridation plant of fill and draw type is recommended. The plant consists of a hopper-bottom cylindrical tank with a depth of 2m. The diameter depends upon the quantity of the water to be treated. All unit operations of mixing, flocculation and sedimentation are performed in the same vessel. It has a stirring mechanism, which can be either hand operated or power driven. Raw water is pumped to the unit and required quantity of alum, lime and bleaching powder are added. The contents are stirred for 10 min and allowed to settle for 1-2 hours. The settled sludge is discarded and the defluoridated supernatant is filtered and supplied through stand posts.

Fill-and-Draw defluoridation plant for rural water supply

The raw water from the source is pumped to the reaction-cum-sedimentation tank which is referred to as reactor. The reactors are made of Ferro-cement or RCC and are circular in shape with dished bottom and epoxy coating, in case of RCC. The top portion of the reactor is covered with a sturdy lid. A manhole with a lid is provided for inspection and to pour chemicals into the reactor. An operation platform is raised on girders 10 cm above the top of the reactor. The stirring mechanism, consisting of motor, reduction gear, paddles, and shaft is mounted on the platform. A ladder with a pipe railing across the platform is provided. The settled water outlet with sluice valve is connected to inlet of sump well. To withdraw the settled sludge once daily and dispose it on the sludge drying beds, a sludge pipe with sluice valve is provided.

Nalgonda technique for domestic defluoridation

Any container of 20-50 lit capacity is suitable for this purpose. A tap, fitted 3-5 cm above the bottom of the container is useful to withdraw treated water but is not essential. Adequate amount of lime water and bleaching powder are added to raw water and mixed well. Alum solution is added to it and stirred for 10 min. The contents are allowed to settle for 1 hour and the clear water is withdrawn either through the tap or decanted slowly, without disturbing the sediment and filtered. The settled sludge may be discarded away from the source of water or preferably collected and sent for recycling.

Advantages of Nalgonda technique

Regeneration of media is not required

1. No handling of acids and alkalies

2. The chemicals required are readily available and are used in conventional municipal water treatment.

3. Adaptable to domestic use.

4. Economical

5. Can be used to treat water in large quantities for community usage.

6. Simplicity of design, construction, operation and maintenance.

7. Local workers can be readily employed.

8. Highly efficient removal of fluorides from high levels to desirable levels.

9. Little wastage of water and least disposal problems.

10. Needs minimum of mechanical and electrical equipment.

11. No energy, except muscle power is required for domestic equipment.

12. Provides de-fluoridated water of uniform acceptable quality.

Disadvantages of Nalgonda technique

Hardness of the raw water in the range of 200 mg/l to 600 mg/l requires precipitation softening and beyond 600 mg/l becomes a cause for rejection or adoption of desalination.

1. Generation of higher quantity of sludge compared to electrochemical defluoridation [14].

2. The large amount of alum needed to remove fluoride.

3. Careful pH control of treated water is required.

Adoption of Nalgonda technique

The Nalgonda technique is normally adopted when the area under consideration has following characteristic features :

1. Absence of acceptable, alternate low fluoride source within transportable distance.

2. Total dissolved solids below 1500 mg/l

3. Total hardness is below 600 mg/l.

4. Alkalinity of the water to be treated must be sufficient to ensure complete hydrolysis of alum added to it and to retain a minimum residual alkalinity in the treated water to achieve a pH of 6.5 - 8.5.

5. Raw water fluorides ranging from 1.5 - 20 mgF/l.

Two bucket technique in Tanzania

The Nalgonda Technique has been introduced in African villages and studied at pilot scale in Kenya, Senegal and Tanzania [26]. The original technique was modified to overcome the limitations. The designed defluoridator consists of two buckets equipped with taps and a sieve on which a cotton cloth is placed. Alum and lime are added simultaneously to the raw water bucket where it is dissolved/ suspended by stirring with a wooden paddle. The villagers are trained to stir fast while counting to 60 (1 minute) and then slowly while counting to 300 (5 minutes). The flocs formed are left to settle for about one hour. The treated water is then tapped through the cloth into the treated water bucket from where it is collected as needed for drinking and cooking. Investigations had shown that at least some of the fluoride, which has been captured in the flocs, is released slowly back to the water. The use of two buckets should thus ensure that the treated water is separated from the fluoride containing sludge directly after the defluoridation. All physico- chemical processes are thus performed in the raw water bucket, while the treated water bucket is kept only for the storage of the defluoridated water. Both containers are 20 litre plastic buckets, supplied with covers and equipped with one tap each, 5cm above the bottom to enable trapping of sludge. The sieve acts as an extra safety device collecting any flocs which may escape through the tap in the raw water bucket. Normally, the water is completely clear, because the flocculation and sedimentation also remove water turbidity.2

IISc Method

The Indian Institute of Science (IISc), Bangalore developed a simple defluoridation technique which uses Magnesium oxide, lime and Sodium bisulphate. Magnesium oxide removes dissolved fluoride ions from water samples by precipitating fluoride as insoluble Magnesium fluoride.

MgO + H2O Mg(OH)2

Mg(OH)2 +2NaF MgF2+2NaOH

Due to MgO, the pH of treated water is 10-11. It is adjusted to desirable levels (6.5 to 8.5) by adding 0.15 to 0.2 g of Sodium bisulphate per liter water. If bicarbonate ion concentration of water is more than 200 ppm, it interferes with the function of Sodium bisulphate. To overcome this bicarbonate interference, 0.3 mg of lime and 0.8mg of MgO are added per liter water. A simple domestic defluoridation unit was developed to treat 15 liters of fluoride contaminated water by this method.

Other techniques of defluoridation

Reverse osmosis and electro dialysis are physical methods that are tested for defluoridation of water. Though they are effective in removing fluoride salts from water, there are certain procedural disadvantages that limit their usage on a large scale.

Reverse Osmosis and Electro dialysis

In reverse osmosis, the hydraulic pressure is exerted on one side of the semi permeable membrane which forces the water across the membrane leaving the salts behind. The relative size of the pollutants left behind depends on the pressure exerted on the membrane. In electro dialysis, the membranes allow the ions to pass but not the water. The driving force is an electric current which carries the ions through the membranes (Hall and Crow, 1993). The basic principle of the process is the adsorption of fluoride with freshly precipitated aluminum hydroxide, which is generated by the anodic dissolution of aluminum or its alloys in an electro chemical cell. The process utilizes 0.3 to 0.6 kwh of electricity per 1000 liter of water containing 5 to 10 mg/l of fluoride. The anode is continuously consumed and needs to be replenished. The process generates sludge at the rate of 80-100 gm per 1000 liters

The removal of fluoride in the reverse osmosis process had been reported to vary from 45 to 90 % as the pH of the water was raised from 5.5 to 7. The membranes are very sensitive to pH and temperature. The economics of the approach also deserves evaluation under specific circumstances.2,3,4

Current status of defluoridation in India

UNICEF has worked closely with the government and other partners in defluoridation programmes in India, where excessive fluoride has been known for many years to exist in much of the nation's groundwater.

In the 1980s, UNICEF supported the Government's Technology Mission in the effort to identify and address the fluoride problem. Government of India launched a massive programme, namely “Technology Mission on Safe Drinking Water” in 1986 with the goal of providing potable water to the people living in rural India. It was renamed as “Rajiv Gandhi National Drinking water Mission” in 1991. A sub-mission on “control of fluorosis” was included in this ambitious program.

UNICEF's focus in the Indian programme has been on strengthening the systems for monitoring water quality, facilitating water treatment by households and advocating alternative water supplies when necessary. Education of households and communities is the key to the strategy. A number of demonstration projects have been initiated in fluorosis-affected areas, with the emphasis currently on introducing household defluoridation. UNICEF has also sponsored research and development on the use of activated alumina for removal of fluoride from water. Under National drinking water scheme of Government of India, 16 villages of Mehsana district, Gujarat were provided with defluoridation plants at the cost of Rs. 106 lakh. However, due to exorbitantly high cost of (approximately Rs1.5 lakh/year) maintenance and repairing, most of the plants are non-functional.40 Similar situation exists in many other states throughout the country. With a view to resolve the problem of water scarcity and high fluoride concentration in drinking water the Government of Gujarat has identified a few long term schemes. Some of the schemes are :

1. Dharoi Reservoir Dependent Scheme

371 villages belonging to Kheralu, Sidhpur, Visnagar and Patan taluka will be provided with the 68.86 MLD of water under group water supply scheme, at an estimated cost of Rs. 140 Crore.

Sabarmati River Dependent Scheme

109 villages from Vijapur Taluka will be provided with water drawn from Sabarmati river at an estimated cost of Rs. 36 Crore.

Narmada Canal Dependent Scheme

111 villages belonging to Chanasma Taluka, 118 villages belonging to Kadi Taluka and a large number of villages belonging to Sami and Harij taluka will be provided with the water from Narmada main canal by constructing necessary storage tanks and filtration plants. The experience of villagers with several existing regional water supply schemes is, however, not very satisfactory.2

Defluoridation – Studies in India

Activated Alumina (AA) :

Prasanti Technology using Activated Alumina

This was the result of research and development activities carried out at the Bio-Science Department of Satya Sai University for Higher learning in Prasanti Nilayam in Anantpur district, Andhra Pradesh.

• Alumina (Al2O3) is practically insoluble in water.

• Using activated alumina technology, both community and domestic defluoridation can be carried out.

• 25 community defluoridation plants, each serving approximately 200-400 people at a cost of Rs.35, 000/plant have been installed.

• Around 500 domestic delfuoridation filters are also used by people living in endemic areas. Experiences of UNICEF in India using House hold based defluoridation using activated alumina

UNICEF supported the research for development of technology along with Water, Environment, Sanitation Section (WESS) by the Department of Chemistry, IIT Kanpur. Pilot projects were taken up in Andhra Pradesh and Rajasthan in 1996-2002.

Pilot Project in Andhra Pradesh

• Kadiri Mandal of Ananthpur district is a chronic high fluoride area.

• Domestic defluoridation unit was installed in 98- 99 with assistance from UNICEF and local NGO Mytry Social Service Society.

Project implemented in three phases

Phase I : Carried out in 1998 in 6 villages. DDFUs with plastic containers using AA were used. 30 units supplied at the cost of Rs.410/unit. Regeneration of AA was done at Panchayat Raj Engineering Department in Kadiri.

Phase II : Carried out in 1999-2000 in 25 villages. 2000 DDFU made of stainless steel chambers distributed at unit cost of Rs.1000. Regeneration of AA carried out at Rural Sanitary Mart in kadiri. Given at Rs.250/unit to BPL families and Rs.400/unit to APL families.

Phase III : Expansion was carried out to 25 more villages at the same cost as in Phase II. 1800 units were distributed in 2000-01 and 1000 units in 2001-02. Regeneration of AA was carried out at village level.

By June 2003, Mytry had 60 dealers in AP and 20 in Karnataka. About 60000 filters had been marketed.

Practical Problems

• Disposal of effluents

• Long time required for the regeneration of activated alumina.

Pilot Project in Rajasthan

Out of the 32 districts in Rajasthan 22 are fluoride affected. 16,560 villages are affected by high fluoride. UNICEF assisted two NGOs SKIACH and SARITA for pilot project in Dungarpur since 1996. The project has spread to 120 villages in Dungarpur and around 1800 DDUs were processed by UNICEF and distributed. By Mid 2003, 24000 DDUs had been distributed in 5 districts of Rajasthan through government agencies.

KRASS Defluoridation Process

Fluoride contaminated water is passed through a bed of specially designed filter media to get defluoridated water. The process has been verified by CSIR and PHED of Rajasthan.

Advantages

• Simple process and cost effective It is a practical approach for rural population.

• Easy to use for illiterate villagers.

• Minimal involvement of technical personnel.

• Once laid down, the only expenditure is that of recharging according to the capacity of the filter.

• The exhausted media bed can be easily recharged without replacing the material at least for 40 cycles.

• The process achieves better removal of suspended matter, better clarity and maintains taste of water.

• The treatment cost is around 0.6 — 0.8 paise / per litre at 10 ppm of fluoride.

Carbion

Pilot Plant

Using carbion and defluoron-1 in 8:1 proportion was installed at Gangapur (Rajasthan). Filter alum of 2, 3, 5, 6 and 10% were used to regenerate the mixed medium. The fluoride content of raw water was 4.8 mg/litre. Most of defluoron-1 was washed out in the first few cycles. Cost of treatment: Rs.0.3 / m3 of water with 4.3 mg/liter fluoride.

Plant Studies

Two plants with a capacity to treat 20,000 gal per regeneration were installed at Municipal Corporation, Nalgonda and CTI, Hyderabad. The plant had a pressure shell, regeneration tank and a storage reservoir of 4-6 liters capacity. Water is passed through a bed of defluoron-2 medium contained in a cylindrical steel shell to which are attached pipe work and control.1,2,3,4,5

Indion Delfuoridation Hand pump Attachment

• Installed at Mangi Kolam site in Yavatmal district in Rural Maharashtra.

• The fluoride content of ground water reduced to 0.304 ppm from 8.73 ppm.

• Installed also at Nanded and Nagpur.

• Approved by Government of Maharasthra.

• 67 defluoridation units have been installed at Yavatmal.

Public Health Significance

Fluorosis is an important public health problem in India. The United Nations Environmental Program (UNEP) currently estimates that the number of individuals affected by fluorosis is in the tens of millions across at least 25 countries in both developed and developing nations. The drinking water sources in India have been reported with fluoride concentration as high as 30mg/l. Excess fluoride in drinking water is prevalent in 150 districts of 17 States of the country. Hence, it becomes necessary to bring down the fluoride concentration within permissible limit of 1.5mg/l according to Indian Standards. Innovative methods of defluoridation should not be confined to the labs, rather should find its way to be practical in the field. Appropriate community organization and co-operation is necessary for the success of community defluoridation.

Conclusion

Water is the main source of intake of fluoride. Though not life threatening, this disease causes impairment of dental esthetics, derangement of skeletal system which results in compromised quality of life. There is no cure to the disease and prevention is the only solution. The first and foremost preventive measure is drinking fluoride-safe water. This can be accomplished by defluoridation of fluoride-contaminated drinking water. Defluoridation should be taken up where there is no alternate source of safe drinking water. So far Nalgonda technique is the most suitable technique for Indian rural communities. Governments should establish the community defluoridation plants and sanction sufficient funds for their maintenance. Communities should be educated and encouraged to actively participate in the procedure. The advantage of the community defluoridation over domestic defluoridation is uniformity of the procedure and hence, better quality control. Where community defluoridation is not feasible, the residents of the endemic fluorosis areas should be educated and motivated to adopt domestic defluoridation techniques. Suitable technique for the community should be identified. It should be economic, adoptable and acceptable to the community. Priority should be given to techniques, which utilize locally available materials as defluoridation agents. Regular supply of the materials and equipment should be ensured by means of techniques such as social marketing.

References

- Eswar P, Devaraj C G. Water defluoridation: Field studies in India. Indian journal of Dental Advancements.2011;3(2):526-533.

- Renuka P, Pushpanjali K. Review on Defluoridation Techniques of Water The International Journal Of Engineering And Science.2013;2(3):86-94.

- Khichar M, Kumbhat S. Defluoridation - A review of water from aluminium and alumina based compound International Journal of Chemical Studies 2015; 2(5): 04-11.

- 4. Ingle NA, Dubey HV, Kaur N, Sharma I. Defluoridation techniques : Which one to choose. Journal of Health Research and Reviews 2014;1(1):1-4.

- Arlappa N, Qureshi A, Srinivas Fluorosis in India: an overview Int J Res Dev Health 2013; 1(2):97-102.

- Park K. Textbook of Preventive and Social Medicine 21st edition.Jabalpur,India:M/s Banarsidas Bhanot; pg.577.

- Ole Fejerskov, Jan Ekstrand, Brian A. Burt. Fluoride in Dentistry. 2nd Ed;Munksgaard: John Wiley & Sons, Limited; 1996. p.167.

- A.K. Susheela, Epidemiology And Control Of Fluorosis In India, J of Nutrition foundation of India,1984.

- 9.Hiremath S.S. Textbook of Preventive and community Dentistry. 2nd ed. New Delhi, Elsevier Publications :2011. p 257-66

- C.M. Marya. A textbook of Public health Dentistry. 1st ed. New Delhi. Jaypee publishers 2011. p 240-51

- Peter S. Essentials of Preventive and Community Dentistry. 4th Ed. New Delhi. Arya Publishing. 2009. p 221-35.

- Mariappan P, Vasudevan T. Domestic defluoridation techniques and sector approach for fluorosis mitigation.

- Mariappan P, V. Yegnaraman, T. Vasudevan. Defluoridation of Water Using Low Cost Activated Carbons. IJEP 2002;22(2):154 – 160.

- Herschel S. Horowitz and Stanley B. Helfetz. The Effect of Partial Defluoridation of a Water Supply on Dental Fluorosis- Final Results in Bartlett, Texas, AJPH JUNE, 1972; 62(6): 767-9.

- Herschel S.Horowitz, Stanley B.Heifetz, and William S. Driscoll. Partial defluoridation of a community water supply and dental fluorosis. Health service reports,1972; 87(5): 451-455.

- Fluorosis : Treatment and prevention. http://www.krassindia.org/fluoride_tre.htm. Accessed on 16/7/15.

Citation: Suvarna V Biradar, Deflouridation – A Review, Asian Journal of Pharmaceutical Technology & Innovation, 6 (27); 01-08, 2018. www.asianpharmtech.com.